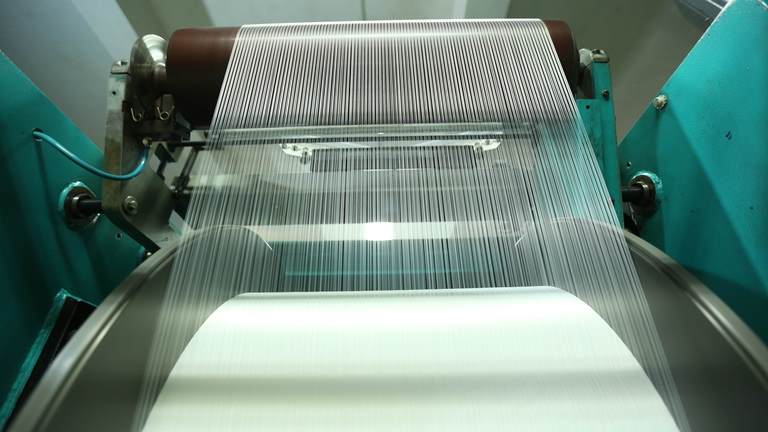

Fibre processing

Auxiliaries and finishes

Anti-static additives

As synthetic fibres tend to be poor conductors of electricity, friction during processing can cause build-up of static charge. This can lead to a variety of processing problems. Croda offers a wide range of anti-static agents that are designed to eliminate processing problems due to static electricity build-up.

Vibrant dyeing

In the dyeing step, pre-treated fabric is dyed with different classes of dyestuff depending on the substrate used and end performance requirements. Croda offer various dye bath additives which ensure trouble-free dyeing and best results in terms of yield, solidity, fabric appearance, fastness, and batch to batch consistency.

Moisture management

Synthetic fibres can often be hydrophobic upon manufacturing, meaning it is difficult for water to pass through the fibre. Our durable finishes can improve the hydrophilic tendencies of synthetic fibres and increase the strike-through.

Fibre and fabric technologies

Dyeing & printing

Finishing

Preparation

Washing off & after treatment

Nonwoven finishes