We create, make and sell bio-based phase change materials (PCMs) that can be used in passive temperature-controlled packaging. Our range of PCMs keep goods at a specific temperature for sustained periods of time, so that they can reach the end destination in the same condition as the goods sent out.

What is temperature-controlled packaging?

Temperature sensitive products such as pharmaceuticals, vaccines and biological materials are required to be maintained within a pre-defined temperature range to ensure that the product quality is preserved.

As such, shipping systems must comply with regional regulations. In the EU, the good distribution practice (GDP) guidelines (2013/C 343/01) require distributors of pharmaceuticals to “demonstrate that the medicines have not been exposed to conditions that may compromise their quality” and this type of legislation is being adopted around the world.

What cold-chain packaging options are available?

Active shippers comprise in-built means of cooling and heating to achieve a stable payload temperature regardless of the external ambient conditions, but significant disadvantages are their size and weight as well as the high up-front cost.

Passive shippers regulate the temperature of the payload by passively managing heat flow between the external environment and the shipper payload.

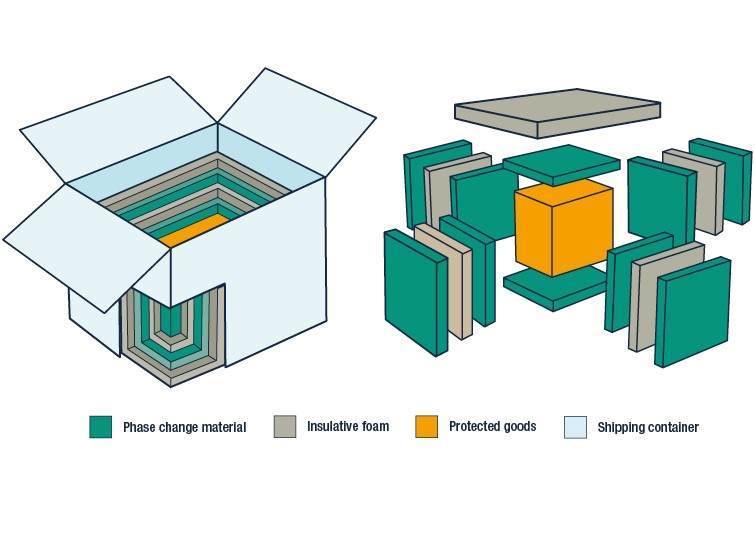

The primary components from outside to inside are the container (box), insulation layer, thermal buffer elements i.e. ice packs or phase change material (PCM) packs and payload at the centre.

Reusable passive shippers consist of durable box often with hollow walls containing insulation. PCM packs are arranged around the centrally located payload. Single use shippers include disposable insulated cardboard cartons and Styrofoam boxes.

Much attention is given to the packaging of products to avoid temperature excursions during the temperature-controlled supply chain.

Temperature-controlled shipping containers and packaging (“shippers”) are a critical part of the cold chain. These packaging solutions are usually a result of both material and system engineering.

Figure 1: A typical temperature controlled shipping container, which uses insulative foam, and PCMs.

PCM packs are sometimes referred to as coolant packs or eutectic packs. Generally, the packs are either rigid plastic (e.g. HDPE) flat containers or flexible plastic pouches. Selection is determined based on factors such as cost, ease of production, compatibility of plastics with the PCM and durability. Rigid packs can contain up to several litres of PCM whereas flexible packs tend to contain up to about 1 litre. Innovative forms of PCM are emerging providing further benefits. For example, CrodaTherm™ bio-based PCMs can be converted into rubbery, shape-stable forms or can be absorbed into shape-stable foam bricks.

Key factors for passive temperature control

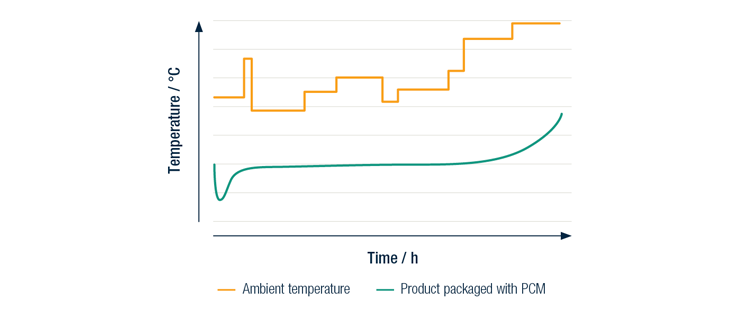

Insulation slows down heat flow between the inside and outside of the shipper while the PCM absorbs or releases heat as required to stabilise the payload temperature. Insulation and PCM are the key components working together to regulate payload temperature.

Key factors influencing the all-important temperature/time profile of the payload are:

- Ambient temperature profile of the shipping lane

- Thickness and thermal conductivity of the insulation material

- The quantity and quality of the PCM.

Figure 2: Temperature profile of external ambient temperature and the temperature controlled package. Goods are kept at a consistent temperature despite varying external conditions.

What is meant by “quality” of the PCM?

By the term “quality” we mean the main properties of the PCM dictating performance in the application. For temperature controlled packaging:

Phase change temperature range (melting & freezing)

Heat capacity (latent heat of fusion).

PCM in a solid state protects against heat gain from higher ambient temperatures by absorbing latent heat during melting. An efficient PCM will melt entirely within a narrow temperature range below the upper temperature limit of the payload.

PCM in a liquid state protects against heat loss due to colder ambient conditions by releasing latent heat during freezing (crystallisation). An efficient PCM will freeze entirely within a narrow temperature range above the lower temperature limit of the payload.

Pre-conditioning of the PCM is important to ensure it is in the correct physical state (solid or liquid) prior to use.

CrodaTherm PCMs provide a combination of high latent heat capacity and sharp melting and freezing profiles ideal for effective and efficient temperature regulation. Examples of CrodaTherm products for isothermal packaging:

| Required temperature | Products(s) |

| 2-8°C | CrodaTherm 5; CrodaTherm 6.5 |

| +/- 10°C | CrodaTherm 9.5 |

| 15-25°C | CrodaTherm 19; CrodaTherm21; CrodaTherm24W |

| +/- 37°C | CrodaTherm 37 |